Automation World

Dorner is Transforming Conveyor Automation by providing cutting edge solutions with best in class support.

We get your product to the exact location, in the exact position, at the exact time it needs to be there for the next phase in the process.

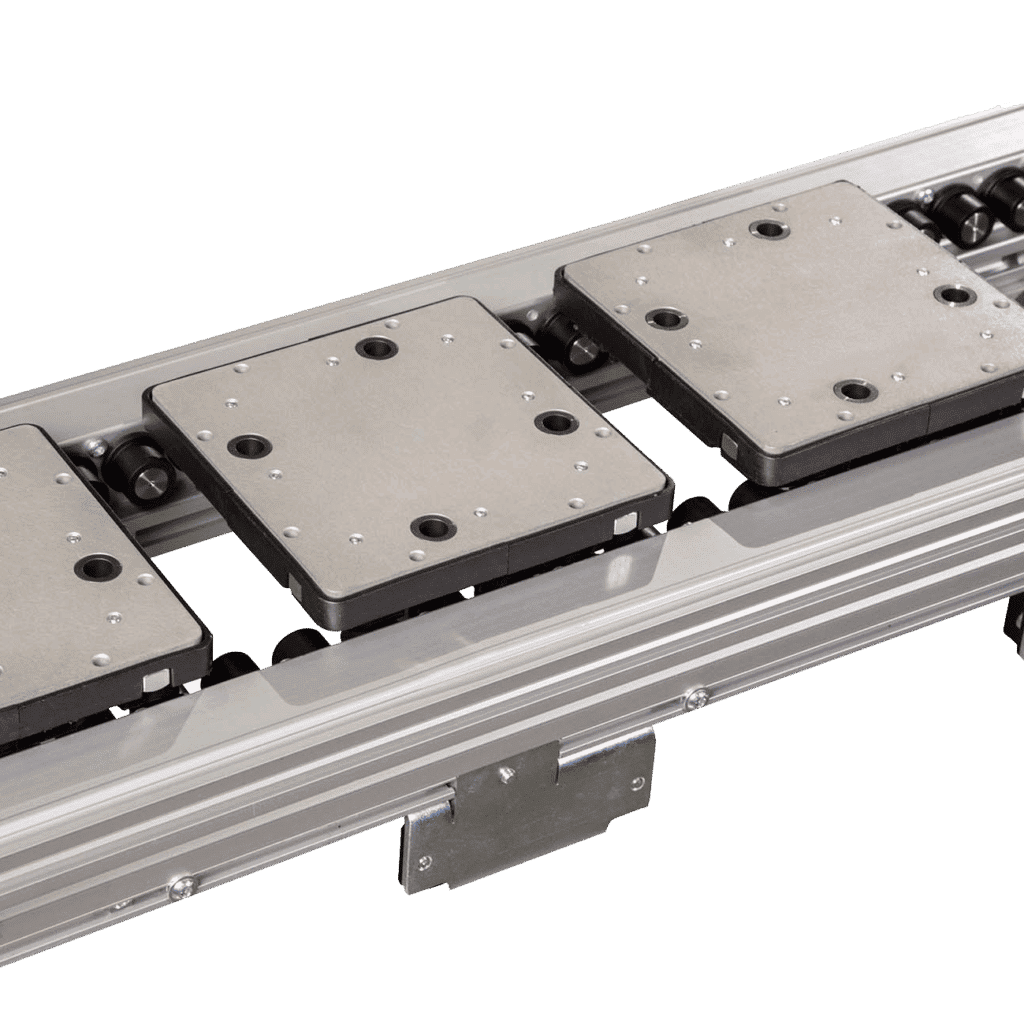

Edge Roller Technology – The Ideal Solution for Cleanroom Applications

Cleanroom manufacturing environments present a unique set of challenges and requirements for any equipment involved, but particularly for the conveyor system. The conveyor in a cleanroom is the machine moving most often throughout the production process, which means it is the most likely to create friction, dust, and carry potential contaminants.

So, what makes the ERT conveyor ideal for cleanrooms?

No Friction Rollers

Rather than a belt, the ERT uses a series of rollers along both edges of the system to move pallets along. The no friction roller system eliminates the debris added to a cleanroom environment by the conveyor and reduces the chance of contaminated product.

Open Frame Design

The open frame design eliminates the chance of small parts falling into the system and getting stuck causing jams. This has a number of benefits including ease of maintenance, reduction in unplanned downtime, and a reduction of areas where debris can build up in the system.

Customizable Zoning

Customizable zoning allows operators to create no contact accumulation zones making it easier to control product flow during the production process. The zoning capabilities also remove the need for pneumatics which release unwanted air in cleanroom environments.

Static Conductive Pallet Skirt

In some manufacturing applications, the dispersion and elimination of static is vital to ensuring delicate electrical components remain properly functional and healthy throughout production. Our ERT pallets are built with static conductive skirts to reduce the risk of static charges affecting the product during assembly.

Choosing a Pallet System eBook

Download eBook

Find The Right Conveyor

Product Page

Explore Dorner’s broad range of conveyor platforms.

DTools

Build a conveyor to your exact specifications, or use our Product Selector to let us help you find the right conveyor for your application.

Videos

See Dorner’s conveyors in action.