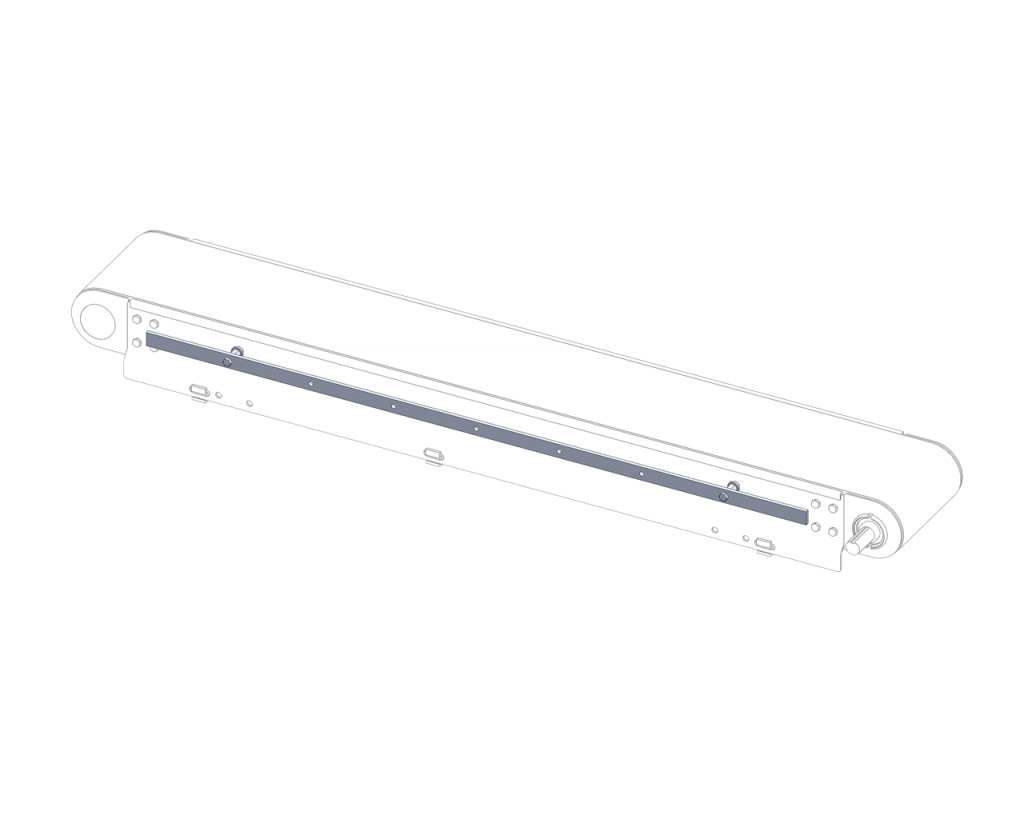

LPZ (Z-Frame) Modular Flat Belt

Contact Us

Conveyor specialists are ready to help you find the right solution

Features & Benefits of AquaGard 7350 Z-Frame Flat Belt Conveyor:

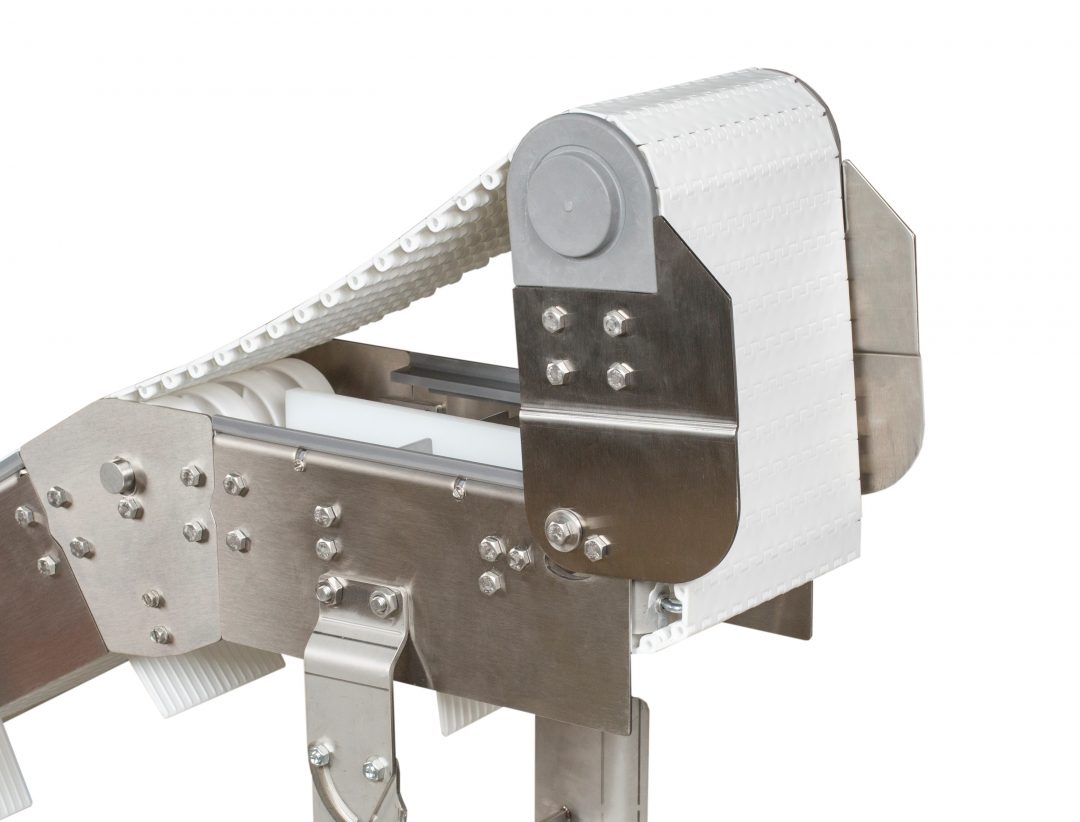

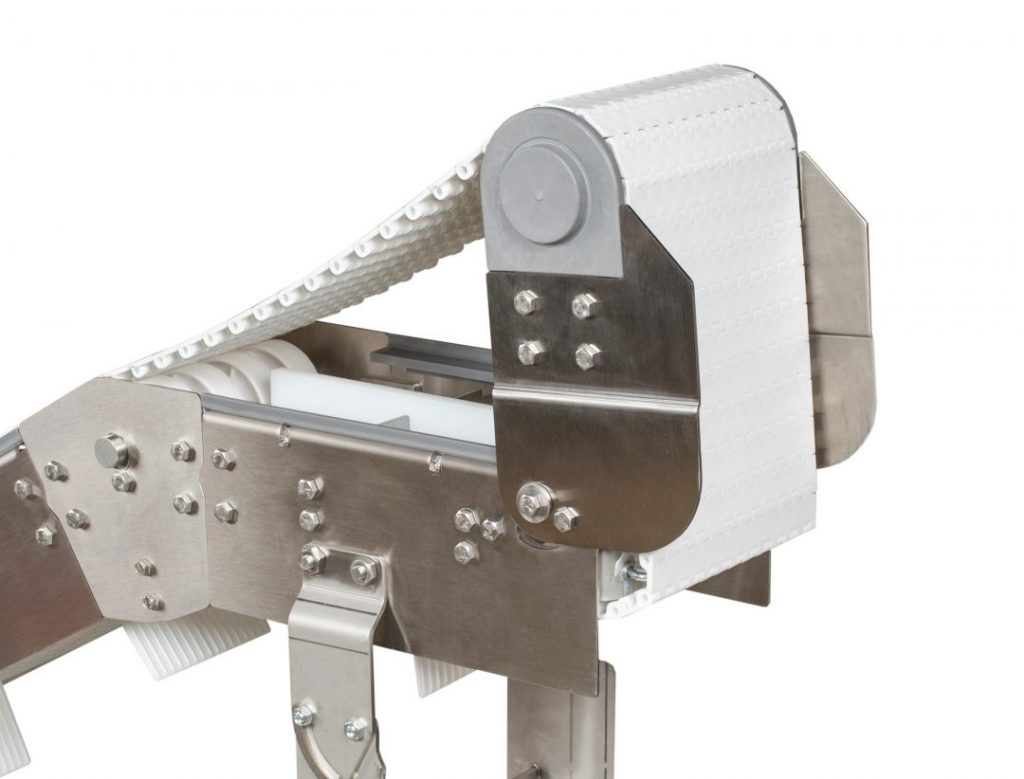

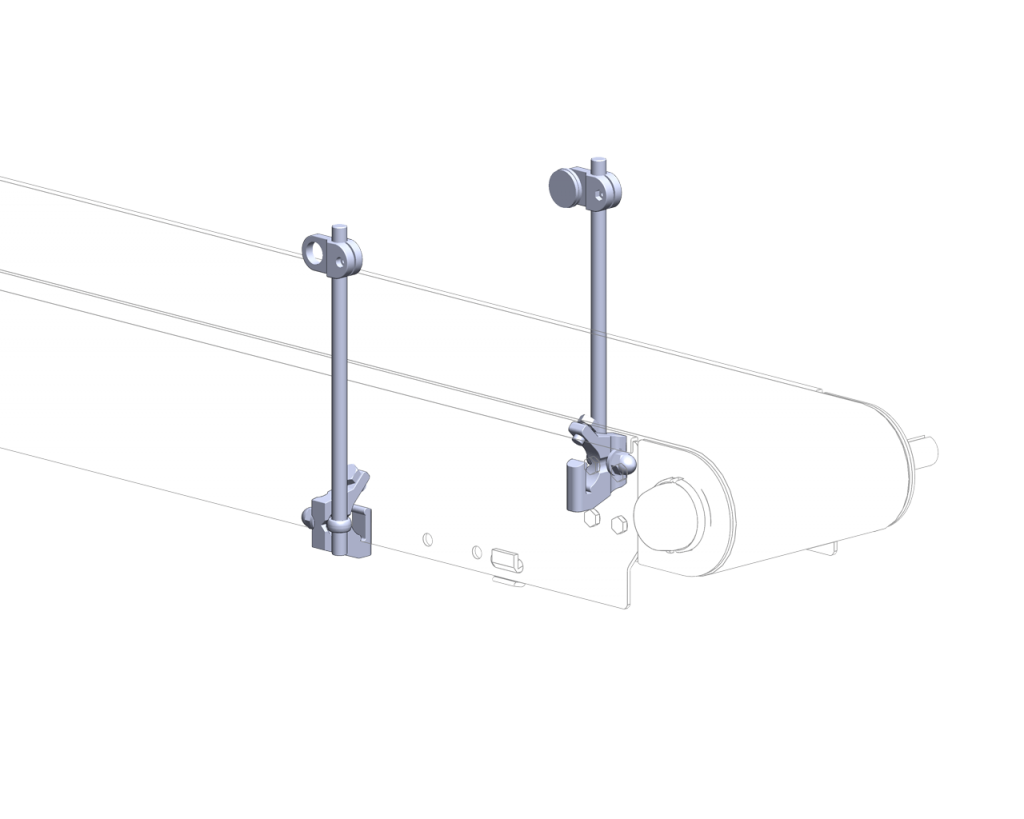

- Tip-up Tails for access inside conveyor for cleaning and maintenance

- Flat sides allow for flexibility when mounting accessories, interfacing with other equipment or transferring products

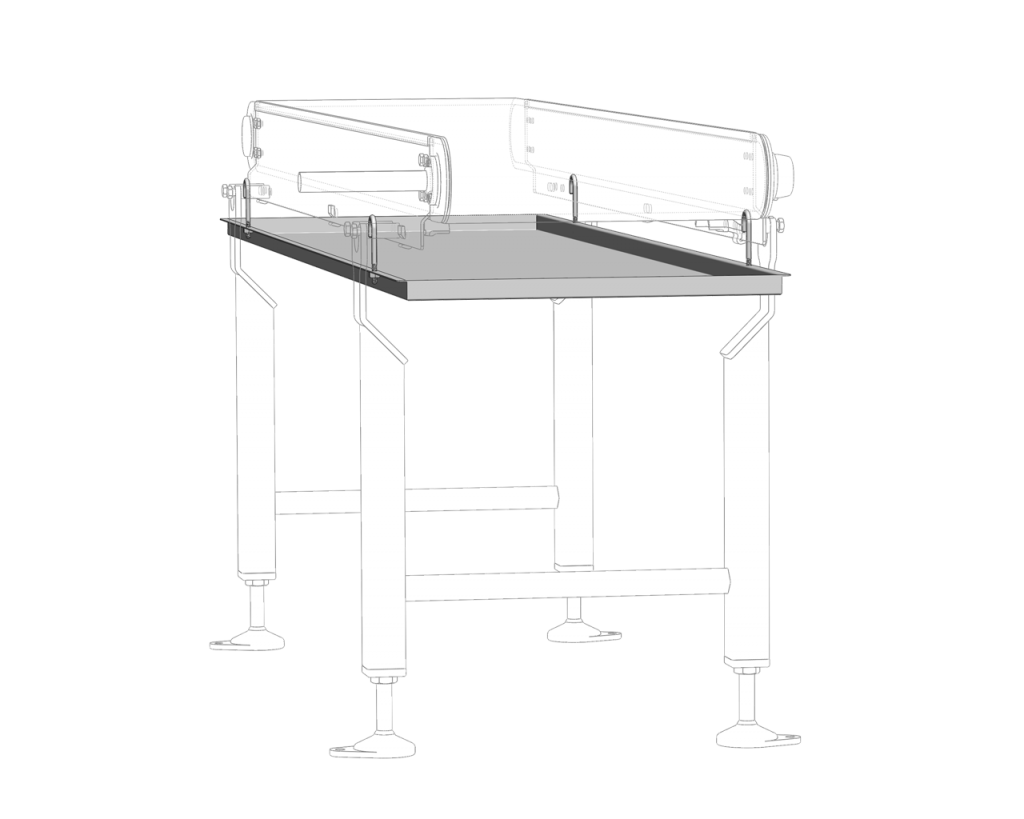

- Minimal horizontal surfaces for easy to clean sanitary surfaces

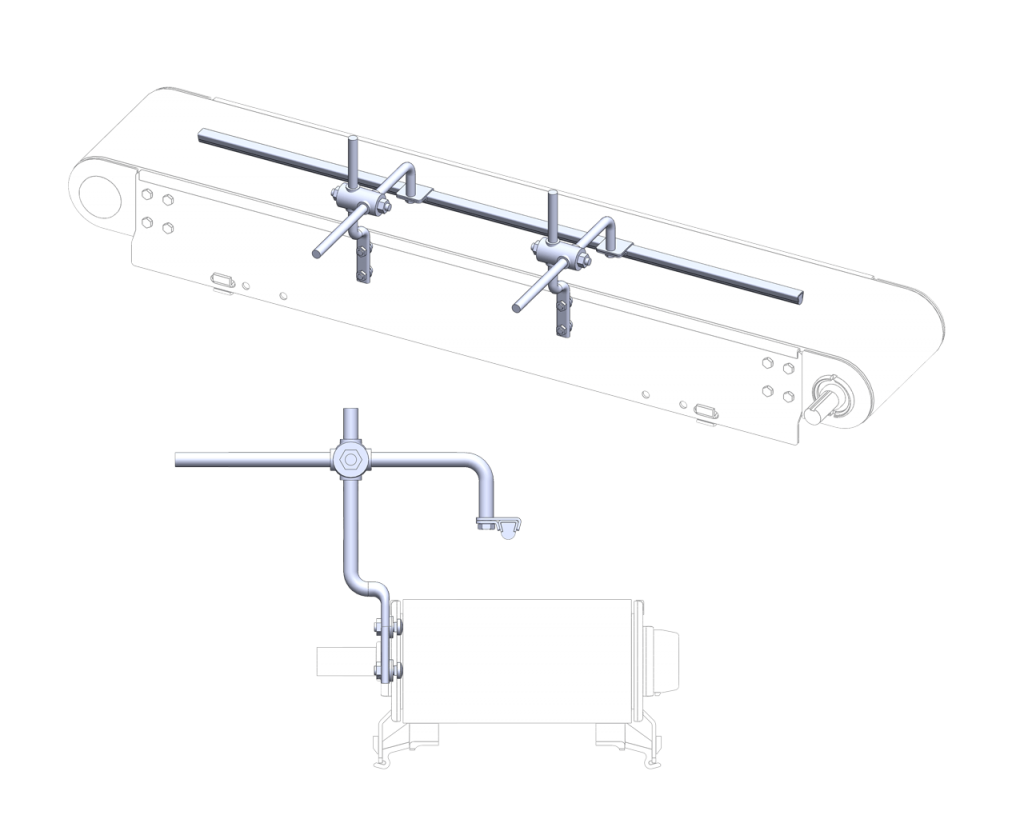

- Micropitch powered transfer for end transfer of product as small as 75 mm (3 in) long

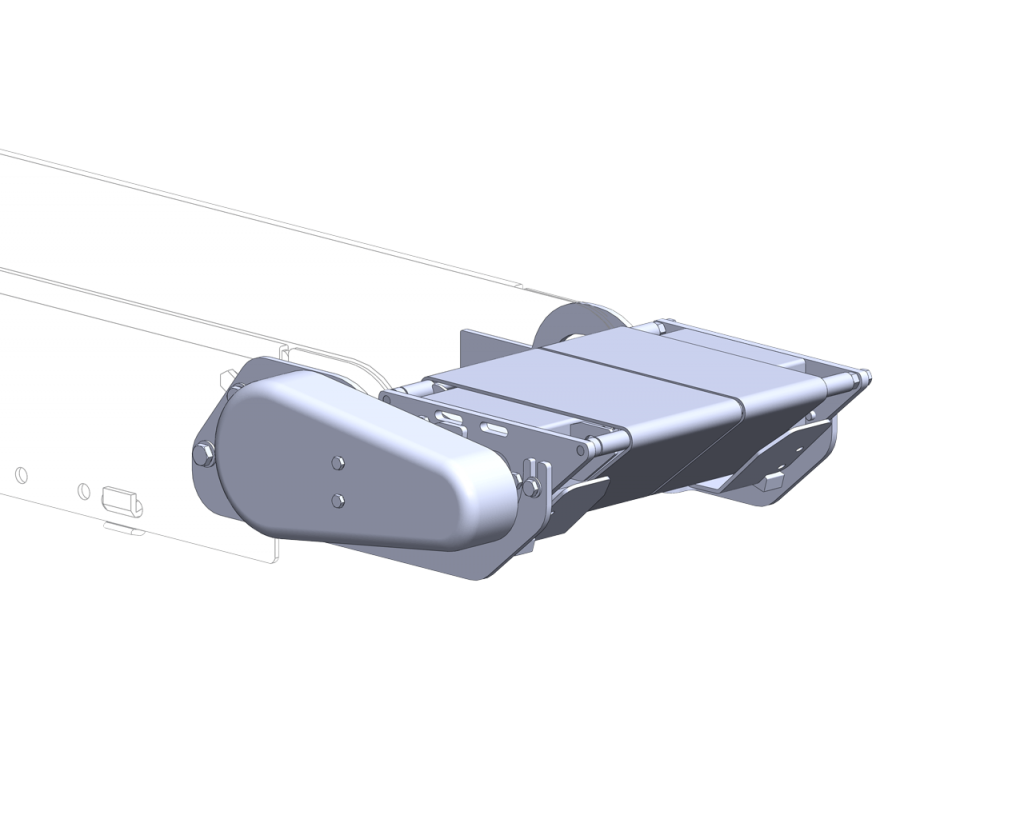

- Side & bottom mount motor package for application flexibility

- Robust open leg support stands with 7 gauge welded stainless steel

Specifications

- Loads up to 45 kg (100 lbs) or 98 kg/sq m (20 lbs/sq ft)*

- Belt speeds up to 78.6 m/min (260 ft/min)

- Belt widths: 203 mm (8 in) to 610 mm (24 in)

- Conveyor section lengths: 610 mm (24 in) to 6100 mm(240 in)

- Maximum total conveyor length of 12190 mm (480 in)

- Optional tip-up tail feature

- Angles from 5 degrees to 30 degrees in 5 degree increments

- Bolt-together Stainless Steel Frame

- FDA approved belting and plastic components

- Suitable for use in wet environments

- Stainless Steel construction for wipe down and low pressure washdown with non-caustic solutions

- Accessories

- Profiles

- Fabric Belting

- Modular Belting

- Support Stands

- Gearmotors

- Drive Mount Packages

- Manuals & Literature

Accessories

Profiles

Fabric Belting

Modular Belting

Support Stands

Gearmotors

Drive Mount Packages

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| AquaGard 7350 Series Manual | 76 | 12.73 MB |

| Literature | Pages | File Size |

| AquaGard Conveyors Brochure | 4 | 3.2 MB |

| Sanitary Conveyors Line Card | 6 | 8.9 MB |